燃气轮机叶片结垢原因及解决方法

在某些情况下,燃气轮机叶片上可能会结垢,且难以清除。燃气轮机叶片上结垢的量和质量取决于许多因素,例如燃气轮机的负荷、燃烧温度、燃油的雾化程度、燃油的品质、涡轮的清洗方式等。通常情况下,钒系缓蚀剂在高温下会与燃油中的金属化合物发生反应,生成高熔点的固态无机复盐。大部分复盐会以固体灰分的形式随废气排出,少部分会粘附在叶片表面,大部分可以被冲洗掉,但仍会残留少量,尤其是在静叶片根部,需要在停机检修时用机器清洗。以下仅以燃油规格为例提供原因分析和解决方案,其他可能影响叶片结垢的现场因素需具体情况具体分析。

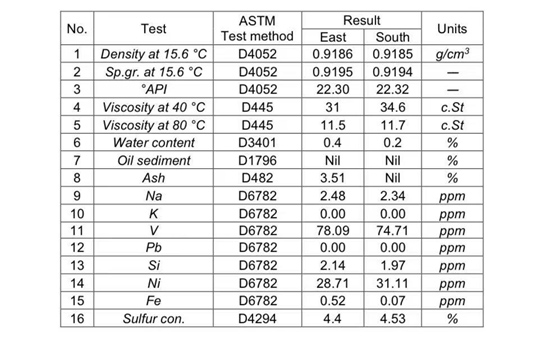

从上表可知,该燃料油属于重质高硫燃料,胶质和沥青质含量较高。如果燃料油进入喷嘴前温度不够高,喷嘴雾化不充分,容易导致燃烧不充分,影响灰渣的蓬松度。硫含量高时,硫燃烧生成的三氧化硫会加速碳氢化合物的聚合,使积碳增多、硬化,影响灰渣的蓬松度,容易粘附在叶片表面形成水垢。规格书中未注明钙含量,钙含量高也是造成水垢硬化的原因之一。现提供以下改进建议供参考:

- 钒缓蚀剂中添加有利于沥青质、胶质的分散燃烧的添加剂,使燃烧更加充分,从而使刀垢更加蓬松,更容易清洗掉。

- 增加具有中和硫氧化物作用的钒系缓蚀剂的用量,降低硫对灰分的影响,也可减轻酸性硫化物对机器的腐蚀。

如果燃料的钙含量较高,建议在燃料油清洗过程中加入脱钙剂,使燃料进入燃气轮机前钙含量低于10ppm。

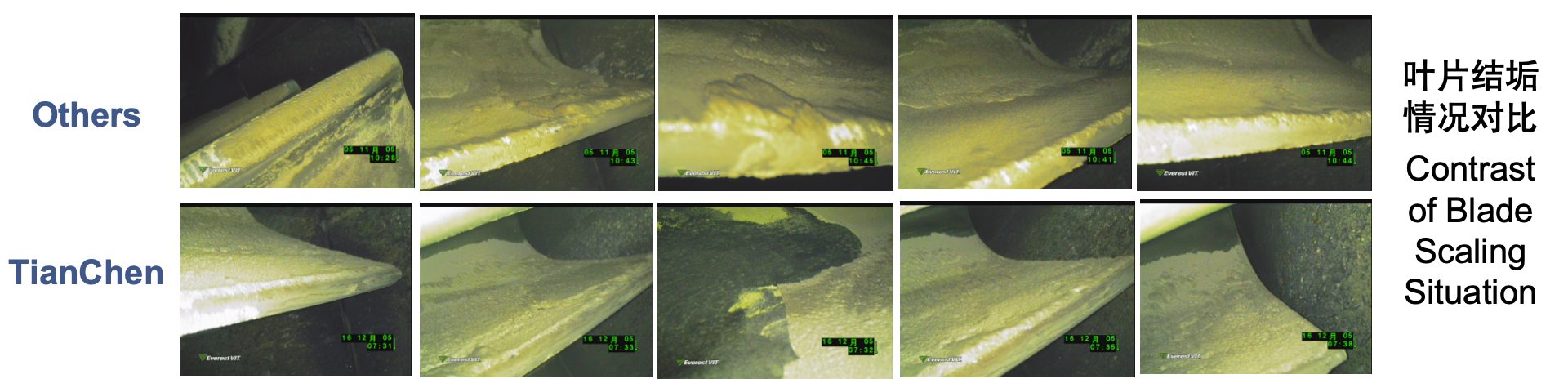

天辰(TC)钒缓蚀剂与其他钒缓蚀剂性能对比: